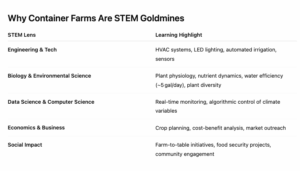

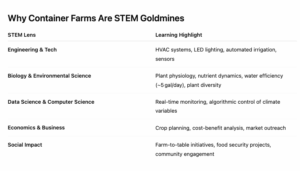

When STEM meets sustainable agriculture, it cultivates far more than fresh food—it grows future innovators. Across the U.S., pioneering schools are partnering with FarmBox Foods to deploy container-based hydroponic farms as immersive, hands-on classrooms. Here’s how a few standout programs are turning shipping containers into living laboratories.

🌾 South Carolina Governor’s School for Science & Mathematics (GSSM)

In Hartsville, SC, GSSM launched a Hydroponic Research Lab, a FarmBox container farm customized for cross-disciplinary STEM learning. Installed summer 2022, it’s integrated into residential, online, outreach and engineering programs.

-

Students study everything from biology and chemistry to robotics, computer science, and environmental policy within the container’s regulated climate.

-

Undergrad-level experiments tweak nutrient delivery, pH, humidity and light schedules.

-

It serves as a hub for curriculum development and for hosting K–12 outreach, including STEM Days and Family STEM events.

Dr. Josh Witten, Director of Research & Inquiry at GSSM said GSSM’s Hydroponic Research Lab isn’t necessarily centered on what it can produce, but how it produces, and, perhaps more importantly, why. It’s a venue for all-encompassing lessons in everything from civics and social responsibility to inventing new indoor farming techniques and creating avenues for environmental stewardship that previously didn’t exist. The educational promise is boundless, as are the practical applications that result.

In many respects, encouraging initial failure provides interdisciplinary opportunities for critical thinking and problem solving. GSSM’s students will have the ability to experiment with different controlled environments, study the research findings, and help answer questions about its effects on the agricultural community in its region, state and beyond. The lab will also help students to develop and standardize hydroponic research protocols for model plants used in plant science, plants of interest and plants beneficial to the area.

“The GSSM Hydroponic Research Lab provides unprecedented opportunities for students to engage in meaningful research on issues of worldwide significance right here on the GSSM campus in Hartsville, SC,” said GSSM Director of Research and Inquiry, Dr. Josh Witten.

“Because this lab represents a unique research resource, it will also be a platform for GSSM students, faculty, and staff to collaborate with researchers beyond our campus. These innovative and immersive experiences are a hallmark of the GSSM education, which prepares students to become the problem solvers of tomorrow.”

The container farm contains elements of — and applications for — biology, chemistry, environmental science, engineering, computer science, robotics and economics, and is ‘being used as a teaching tool to engage their creativity,” the school said.

EPIC Campus – Littleton, Colo.

EPIC, a Career Technical Education campus in Littleton, Colo., received its Vertical Hydroponic Farm in summer 2023 and it turned into a much-discussed amenity during the school year. While the FarmBox is used primarily by students working toward their plant science certification, it has touched many other career pathways; it has applications in business, computer science, nutrition and various other areas of study. The harvested veggies go to three places: the Littleton High School cafeteria via nutrition services, a local pizzeria, and Gracefull Café, a nearby pay-what-you-can eatery.

“The kids go deliver to Gracefull Cafe and they would have people in the cafe tell their stories about homelessness, how when you’re homeless, you’re not eating green veggies,” said Mike Montgomery, EPIC’s Natural Resources Pathway Lead and a certified environmental educator. “The kids would come back and that was a lesson that I couldn’t teach, and it was so powerful for the kids. Way more important than learning about photosynthesis.”

The FarmBox has become a centerpiece of the EPIC campus and visitors always want to know what’s going on inside, Montgomery said. The common refrain from faculty, parents and visiting volunteers is they wish a teaching tool like the FarmBox existed when they were in school.

“They’re so impressed by it and what we’re doing,” he said.

VALE – Parker, Colo.

When Venture Academy of Leadership and Entrepreneurship (VALE) in Parker, Colo., was still just an idea, its founders knew they wanted to change the face of education. One idea to make that happen was bringing a FarmBox to the campus. Now that the school’s vertical hydroponic FarmBox is up and running, it’s proving even more valuable and multifaceted than envisioned.

“There’s just something magical about this place and space. When we do tours for incoming parents, they’re wowed by everything we do, but when they come out to the FarmBox, it’s a game-changer. You can feel it,” said LeeAnn Hayen, chief learner and disruptor at VALE.

The FarmBox has applications in science, culinary, business, nutrition and environmental lessons, among many others. It’s just as important for VALE to “turn out human beings who are empathy centered” as it is to teach them Algebra 1, Hayen said.

Generation Alpha “won’t be satisfied with sitting still,” and engagement tools like the FarmBox are what get kids excited about learning, she said.

According to Katy Kollasch, chief intrepreneur and change agent at VALE, learning doesn’t just happen in a textbook or classroom.

When entrepreneurship students are building a business “from seed to application of a product, they are creating this themselves, and they haven’t had the opportunity to do that in a two-dimensional classroom,” she said.

“The FarmBox creates that additional dimension that actually brings learning to life,” Kollasch said.

morgan community college – Fort morgan, Colo.

Morgan Community College received its Vertical Hydroponic Farm in 2024 and immediately drew interest from the community. Kids from all grade levels were invited to tour the farm, as were local stakeholders and dignitaries during two community open houses. Since then, MCC professors have used the FarmBox to teach general sustainable agriculture practices, and have incorporated students from multiple departments, from biology and agronomy to precision forming hardware, business and multimedia graphic design. Thus far, students have successfully grown broccoli, bok choy, parsley, Korean ponytail radishes, cherry tomatoes, arugula, oregano, basil, Mexican mint marigold, Asian green mix, romaine, dill, chives and jalapeños.

Bill Miller, Precision Agriculture Faculty & Division Chair for Career Technical Education programming, said agronomy students choose a specialty crop for their final research project.

“We do it from start to finish and look at how it produces, how long it takes to germinate, how until it’s mature enough to transplant, how did it grow in the walls, what are the nutrient vales,” Miller said.

Just before harvesting, Miller puts out a message to faculty and students and invites them to take produce home. Rising Up, a nonprofit in Morgan County, also regularly picks up fresh veggies for its food bank. “Everyone loves” the FarmBox, and it has become a vital and dynamic teaching tool on the campus, Miller said.