FarmBox Foods’ Vertical Hydroponic Farm was named among the top 10 finalists for this year’s Coolest Thing Made in Colorado competition put on by the Colorado Chamber. See the press release below!

FOR IMMEDIATE RELEASE

August 7, 2025

Contact: CynthiaE@cochamber.com

Top Ten Finalists for 2025 Coolest Thing Made in Colorado Contest Announced

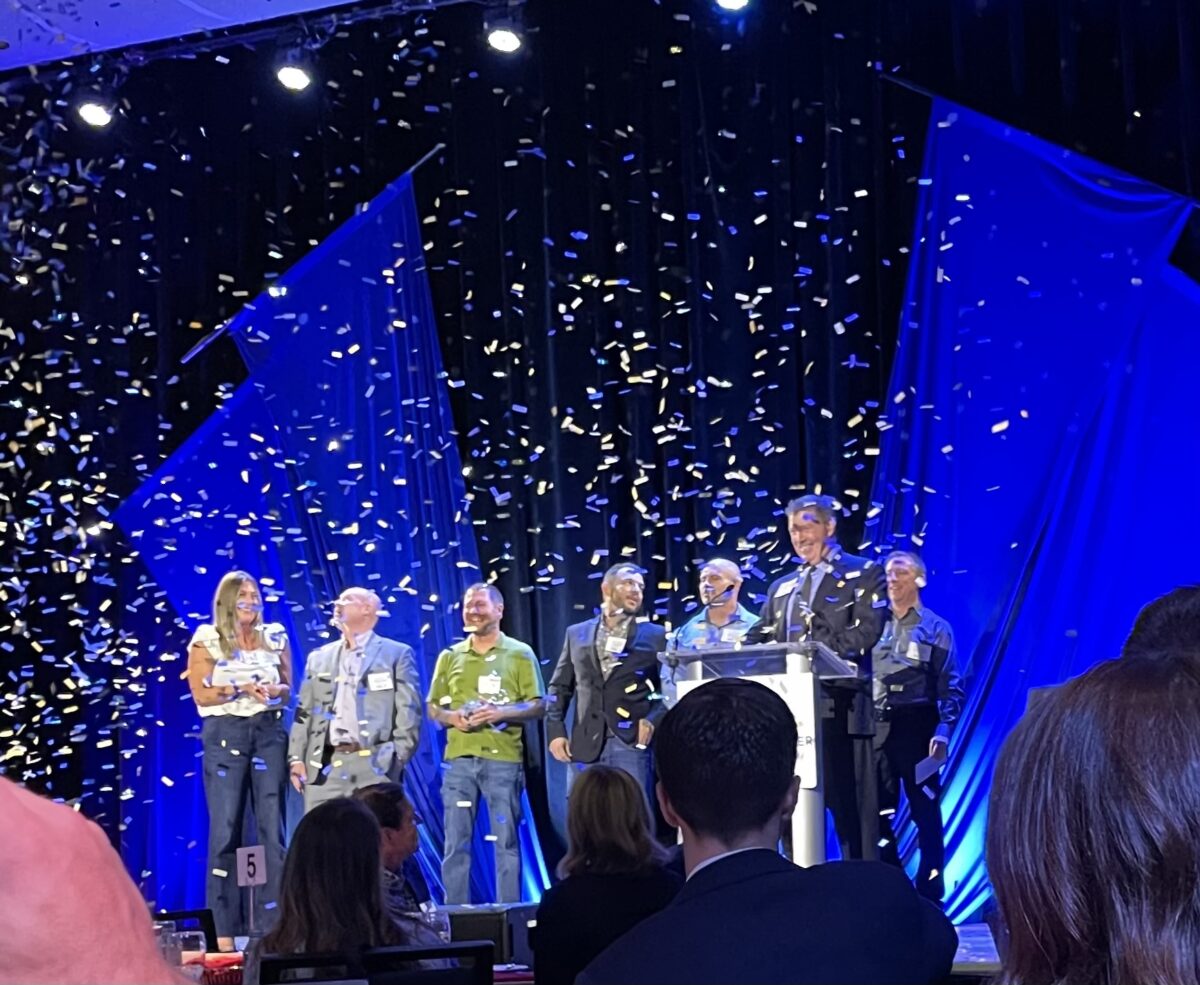

DENVER – The Colorado Chamber of Commerce today announced the top ten finalists for its fourth annual Coolest Thing Made in Colorado competition sponsored by FirstBank.

“This year’s top ten finalists represent Colorado innovation in so many ways,” said Loren Furman, President and CEO of the Colorado Chamber of Commerce. “From breakthroughs in space technology to products that support our farmers, protect our environment, and celebrate our love for the outdoors, these finalists reflect what makes Colorado such a unique place to live and work. We’re proud to highlight these amazing companies and look forward to celebrating them in October.”

The finalists were chosen by an independent selection committee who reviewed and assessed each nomination. The finalists will be honored at the Colorado Chamber’s Coolest Thing Awards Banquet on October 23, where the 2025 winner will be announced and presented with the Coolest Thing Made in Colorado trophy. The Chamber will also announce special categories of winners, including a “People’s Choice” award based on an online voting tool that will launch in the coming weeks.

The Coolest Thing Made in Colorado top ten finalists are as follows:

AE.1 Cosmos by Lightship

The AE.1 Cosmos is the first all-electric aero-electric travel trailer with a 77 kilowatt-hour battery and rooftop solar panels that create a fully self-contained power system. Made in Broomfield, its aerodynamic design and TrekDrive assist system improve towing efficiency and provide up to a week of off-grid living, offering a quiet and low-maintenance option for travel.

AIEye by HapWare

AIEye is a wearable assistive technology that translates nonverbal communication cues such as facial expressions, gestures and body language into discreet haptic feedback for people who are blind, low vision or autistic. The device pairs smart glasses with an integrated camera and a wristband to detect over 25 visual social cues and translates them into distinct, intuitive vibration patterns on the wrist. Made in Golden, AIEye is built for real-world durability, speed and ease of use.

Austere Remediation Unit (ARU-10T) by Austere Environmental

The Austere Remediation Unit (ARU-10T) cleans 10 tons of diesel-contaminated soil per day, removing 99.99% of pollutants and recovering the diesel for reuse. Developed in Golden, Colorado, the system helps prevent water contamination, reduces greenhouse gas emissions, and keeps contaminated soil out of landfills, offering a cleaner and more sustainable solution for waste management.

Autonomous Nano Tractor (ANT) by Barn Owl Precision Agriculture

The Autonomous Nano Tractor (ANT) is a fully electric, self-driving mini tractor engineered in La Junta, Colorado, for small to midsize farms. It handles precision row-crop tasks like weeding, targeted spraying, and planting support, cutting manual labor by more than 50% and reducing input costs by about 30%. Its modular design and advanced computer vision make it a scalable, low-maintenance solution for both regenerative and conventional farms.

Clarity-1 by Albedo

Clarity-1, developed by Albedo in Broomfield, is the first commercial very-low-Earth-orbit (VELO) satellite to 10-centimeter visible imagery and 2-meter long-wave infrared data in a single pass. Launched in March 2025, it marks a breakthrough in multispectral imaging, providing unprecedented detail for applications from city planning to climate research.

Innovaflex Arrays by InnovaFlex Foundry

The InnovaFlex Arrays, manufactured in Colorado Springs, are complex electrical systems built on glass or flexible materials that enable the measurement or application of electrical signals. These arrays have multiple uses, including “Organ-on-a-Chip” applications that allow researchers to study how human tissue responds to pharmaceuticals or treatments, reducing the need for animal testing and supporting more personalized medical approaches.

Laser Maze Challenge by Funovation

The Laser Maze Challenge, manufactured in Longmont, is an interactive attraction where players navigate glowing laser beams, racing against time in three unique game modes that test agility, speed and strategy. With immersive lighting, video replays, and a live leaderboard, it delivers an action-packed experience for families, thrill-seekers and competitive gamers.

Spectra Optia Apheresis System by Terumo Blood and Cell Technologies

The Spectra Optia Apheresis System, developed in Lakewood, is an industry-leading platform for therapeutic apheresis, cell processing, and cell collection, capable of separating and returning blood components while targeting specific cells for treatment or research. First introduced in 2007, it’s now used in over 125 countries to support procedures for hematologic disorders, rare diseases and emerging cell therapies.

The Narwhals by Apex Cool Labs

Manufactured in Boulder, the Narwhals are portable cooling devices designed to quickly reduce core body temperature by targeting specialized vasculature in the palms. Used by professional athletes, firefighters, construction workers, and others exposed to extreme heat, Narwhals help improve heart rate recovery, extend work capacity and provide lasting relief from heat stress in demanding environments.

Vertical Hydroponic Farm by FarmBox Foods

The Vertical Hydroponic Farm, manufactured in Aurora, uses patented vertical farming technology inside upcycled shipping containers to maximize growing space while minimizing water and energy use. These solar-capable, climate-controlled farms enable year-round cultivation of mushrooms, leafy greens and herbs almost anywhere in the world.

Learn more about the Coolest Thing Made in Colorado contest at www.CoolestThingColorado.com.

The Colorado Chamber of Commerce champions free enterprise, a healthy business environment and economic prosperity for all Coloradans. It is the only business association that works to improve the business climate for all sizes of business from a statewide, multi-industry perspective. What the Colorado Chamber accomplishes is good for all businesses, and that’s good for the state’s economy. It was created in 1965 based on the merger with the Colorado Manufacturers’ Association.