GOURMET

MUSHROOM

FARM (GMF™)

FarmBox Foods has designed an efficient, sustainable, and versatile start-to-finish gourmet mushroom farm that is automated, transportable, and solar capable. We have carefully compiled everything you need to grow a wide variety of mushrooms inside a compact space. The possibilities of container farming are endless. Experience farm cultivation and innovation like never before.

SMALL FOOTPRINT, HUGE YIELD

DESIGNED FOR COMMERCIAL SCALE

The state-of-the-art GMF can grow more than 400 pounds of mushrooms per week, year-round. Up to 18 varieties and species of gourmet and medicinal mushrooms can grow simultaneously, including oysters, shiitake, reishi, lion’s mane, chestnut and king trumpets. Our super-efficient layout saves time and labor, allowing the operator to maximize everything the GMF has to offer.

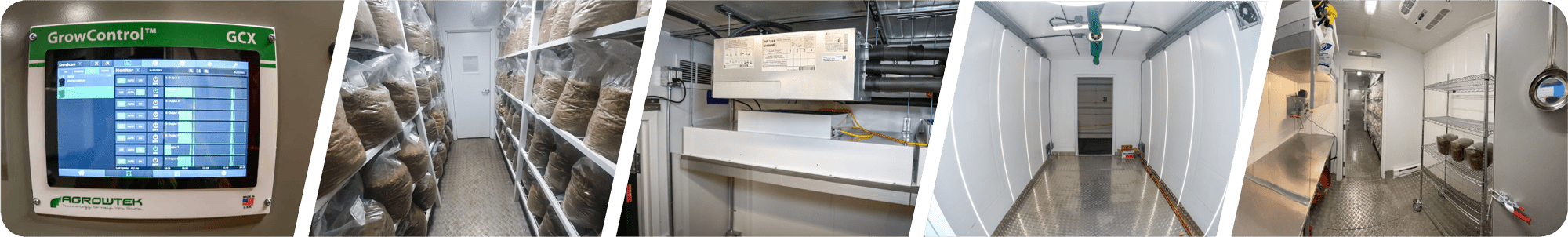

We have brought the best of innovation and automation to our Gourmet Mushroom Farm. The 320-square-foot GMF container takes advantage of every single inch of the shipping container to generate high yields of gourmet mushrooms in a small space. The container design allows it to be controlled and operated by a single person. Our workflow and training will enable your company to scale its mushroom production quickly and efficiently.

AUTOMATION TECHNOLOGY

Each GMF unit is equipped with Agrowtek infrastructure which monitors and controls all climate parameters: Lighting, air exchange, carbon dioxide levels, humidity, and temperature.

SUBSTRATE PREP & PASTEURIZATION

The GMF comes equipped with a batch mixer that handles all kinds of substrates. A built-in steam cabinet pasteurizes the substrate and readies it for inoculation.

REMOTE CONTROL

Monitor and control the farm’s climatic conditions from any smartphone or computer. Alerts can be set up in case any issues arise.

INCUBATION SPACE

There is ample space to incubate all substrate bags. Environmental conditions are closely maintained to optimize mycelial growth.

LAMINAR FLOW CABINET

The GMF lab has six feet of HEPA-filtered workspace. This provides the ideal working environment for inoculations and culture work.

FRUITING CHAMBER

Watch your mushrooms thrive in an ideal growing environment. Temperature, humidity, lighting, and carbon dioxide levels are all monitored and controlled.

GROW WITHOUT PESTICIDES

Even though mushrooms are on the Clean 15 list, that doesn’t mean that they are actually pesticide free! A study done by the FDA shows that 26% of imported mushrooms had more than the allowable amount of pesticides, even thiabendazole, a carcinogen and a developmental and reproductive toxin. Our unique approach to mushroom farming allows you to grow many mushroom varieties, all without using any pesticides whatsoever!

START YOUR FARMING JOURNEY!

From arctic cold to extreme heat, we have put our container technology to the test. Our containers can be customized with solar panels and other solutions to optimize them for your climate and specific needs.